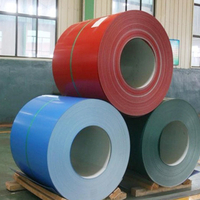

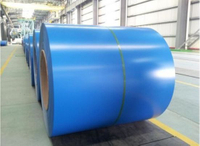

PPGL is pre-painted galvalume steel, also known as Aluzinc steel. The galvalume & aluzinc steel coil uses the cold-rolled steel sheet as a substrate and solidified by 55% aluminum, 43.4% zinc and 1.6% silicon at 600 °C. It combines the physical protection and high durability of aluminum and the electrochemical protection of zinc. It is also called aluzinc steel coil.

Advantage:

Strong corrosion resistance, 3 times that of galvanized steel sheet.

The density of 55% aluminum is smaller than the density of zinc. When the weight is the same and the thickness of the plating layer is the same, the area of the galvalume steel sheet is 3% or larger than that of the galvanized steel sheet.

PPGI Steel Coil Specification

Product Name | PPGL, pre-painted galvalume steel Coil |

Technical Standard | AISI, ASTM, BS, DIN, GB, JIS3312 |

Material | CGCC, DX51D,Q195,Q235 |

Thickness | 0.13-1.20 mm |

Width | 600-1250mm |

Zinc Coating | AZ30--AZ170, Z40--Z275 |

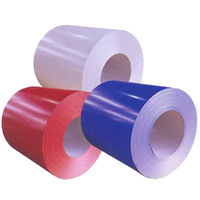

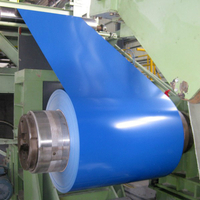

Color | all RAL Colors, or According to Customers Require/Sample |

Coil ID | 508/610mm |

Top Side | Top paint: PVDF,HDP,SMP,PE,PU; Primer paint: Polyurethance, Epoxy, PE |

Back side | Back paint:epoxy,modified polyester |

Surface | Glossy (30%-90%) or Matt |

Coil Weight | 3-8 tons per coil |

Package | Standard export package or customized |

Hardness | soft (normal), hard, full hard(G300-G550) |

T Bend | >=3T |

Reverse Impact | >=9J |

Pencil hardness | >2H |

Salt Spray Resistance | >=500 hours |

The total thickness of the pre-panted galvalume steel coil is composed of the base steel – coating -primer – top paint – protective layer thickness. The top paint thickness is 10-25μm, and the back paint thickness is 5-20μm. The thinner the base steel thickness, the higher the price of the ppgi steel coil, because the processing cost becomes higher.

Usually the paint coating material is polyester (PE) and the color of the back paint is white grey. The color can be customized according to the RAL color card or customer samples. Special patterns can be made, such as wood grain, flower print, camouflage, brick.

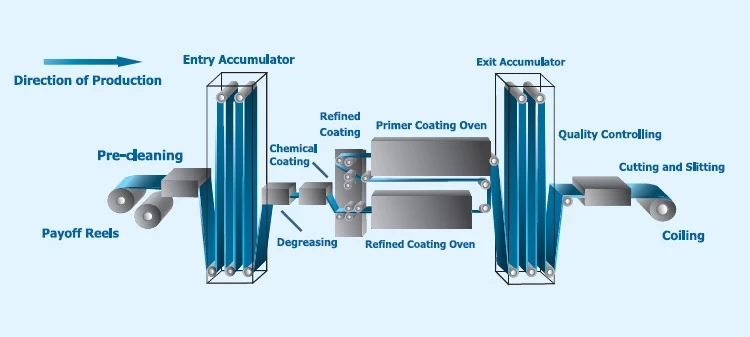

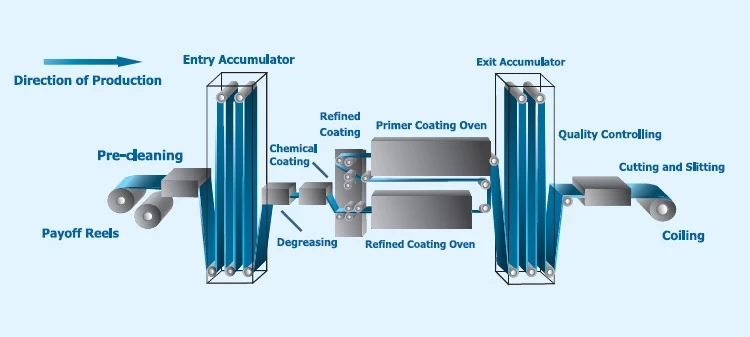

PPGI Production Process Flow Chart

Unrolling → Stitching machine → Entrance loop → Pretreatment → Initial coating → Bake → Cool down → Fine coating → Bake → Embossed film → Export loop → Inspection station → Cut → Coiling

In the above process, if the cleaning degreasing process is not handled well, the adhesion of the primer of the color coated plate to the galvanized sheet is not good, and it is easy to cause the top coat of the color coated steel coil to fall off during the press forming process.

PPGI & PPGL Sheet Coating Layer

Top (Finish) Coating (PE/HDP/PVDF, etc.)

Primer Coating

Pre Treatment (Chromate Coating)

Plating Layer (Zn, AL, 55%AL+Zn)

Base Metal (Cold Rolled Steel Sheet)

Plating Layer (Zn, AL, 55%AL+Zn, Sn, Cr etc.)

Pre Treatment (Chromate Coating)

Functional Painting (Epoxy, Polyester )

PPGI paint coating

| Coating primer | Top paint coating | Service life(years) |

1) Epoxy primer, good adhesion, water resistance, alkali resistance, chemical corrosion resistance, poor single toughness.

2) Polyester primer, good adhesion, good flexibility, sensitive to humid environment, chemical resistance is not as good as epoxy primer.

3) Acrylic primer, good adhesion, good toughness and high pretreatment requirements.

4) polyurethane primer, chemical resistance, abrasion resistance, durability, toughness | 1) Polyester resin, good adhesion, molding and outdoor durability. | 8-10 |

| 2) Silicon Modified Polyester (SMP) | 10-15 |

| 3) High weather resistant polyester (HDP) | 12-15 |

| 4) Polyvinyl fluoride (PVC) | 12-15 |

| 5) Polyvinylidene fluoride/fluorocarbon (PVDF) It has good formability and color retention, good outdoor durability and powder resistance, solvent resistance, limited color and high price. | 12-20 |

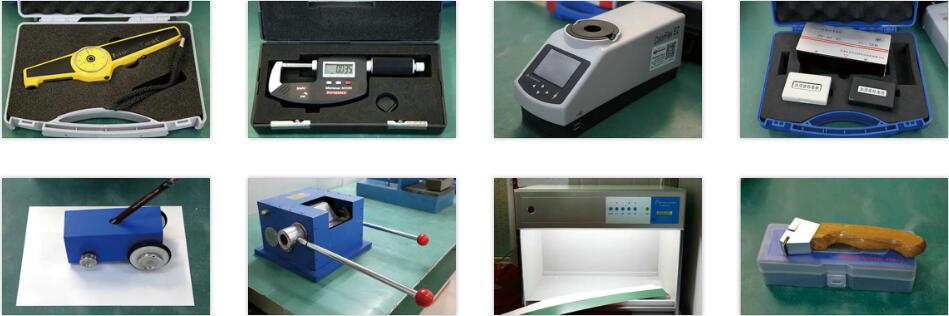

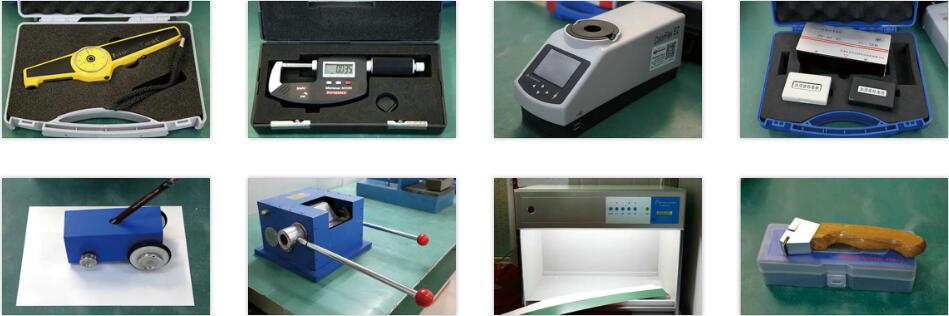

Quality Control

We have our own Physical & Chemical Testing Center Lab. to guarantee our product quality. Our test items & instrument fully meet international standards.

Packing Details

Standard Export Packing:

4 eye bands and 4 circumferential bands in steel

Galvanized metal fluted rings on inner and outer edges

Galvanized metal and waterproof paper wall protection disk

Galvanized metal and waterproof paper around circumference and bore protection

About the sea worthy packaging: extra reinforcement before shipment to ensure that the goods are safer and less damaged to customers.